Energy conservation and environmental protection has

become a hot topic in our country, energy conservation and emission reduction,

green environmental protection has become an unavoidable problem in every

industry, and machinery industry equipment is no exception, as well as the

development of information technology and other related technologies, the

development of environmental protection machinery and equipment in full swing.

Waste tires are full of treasures, containing 16-18% of the steel wire for

high-quality spring steel raw materials: up to 80% of the rubber mixture, can

be made into recycled rubber and vulcanized rubber powder, not only used in the

rubber industry, and widely used in building materials industry, plastic

industry, paint industry and roads, sports venues and many other fields. At

present, the state is increasing its investment in the recycling of renewable

resources and scientific and technological development through various

channels, and supporting key projects that have an impact and take the lead. In

particular, projects for recycling and utilizing renewable resources that

cannot be dealt with at one time and have high production costs and low

economic benefits, but have significant social benefits and are large in

quantity and scope, are proposed to be implemented through the introduction of

foreign talents and funds, promote the improvement of management level of

recycling technology.

Waste tires are known as “Black pollution”, the

accumulation of a large number of waste tires not only occupy land and

seriously damage the environment. Waste tires are not biodegradable due to the

uncertainty of the time required for their decomposition and their components

include elements such as lead, chromium, cadmium and other heavy metals,

improper disposal and management can pose a threat to human health and the

environment. Long-term open piling of waste tires will not only occupy a lot of

land resources, but also easy to breed mosquito-borne diseases, serious

deterioration of the natural environment, and there are fire hazards.

Therefore, how to deal with the increasing quantity of waste tires have become

an urgent environmental problem and the development of supporting industries.

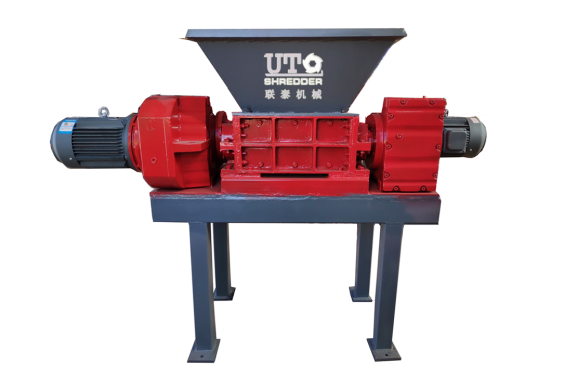

Rubber Shredder is suitable for the crushing and

recycling of many kinds of tires and rubber with many sizes and models. The double

shaft shear shredder made by LianTai machinery is suitable for crushing and

recycling rubber tires of different thickness, height and caliber. The cutting

tool of LianTai mechanical shredder can be customized by the discharge size,

the output can be provided according to the user's

requirements model, LIANTAI mechanical double-shaft shear shredder is also

suitable for heavy-duty solid waste crushing treatment.

We can customize the machine for the customer

according to the customer material, crushing volume and crushing demand.

Welcome to contact us for more detailed product

information. We can recommend the selection of appropriate models, integrated

to meet the production needs of the program. Allow customers to control the

investment as far as possible, access to high cost-effective equipment products

or production lines.

CN

CN EN

EN

TEL:086-0533-3588750

TEL:086-0533-3588750 FAX:086-0533-3588750

FAX:086-0533-3588750 E-MAIL:info@utshredder.com

E-MAIL:info@utshredder.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,