Single shaft shredder and double shaft shredder is a

common shredder type, many customers in the choice of shredder is always

unclear about the difference between the two, let's talk about the difference

between the two.

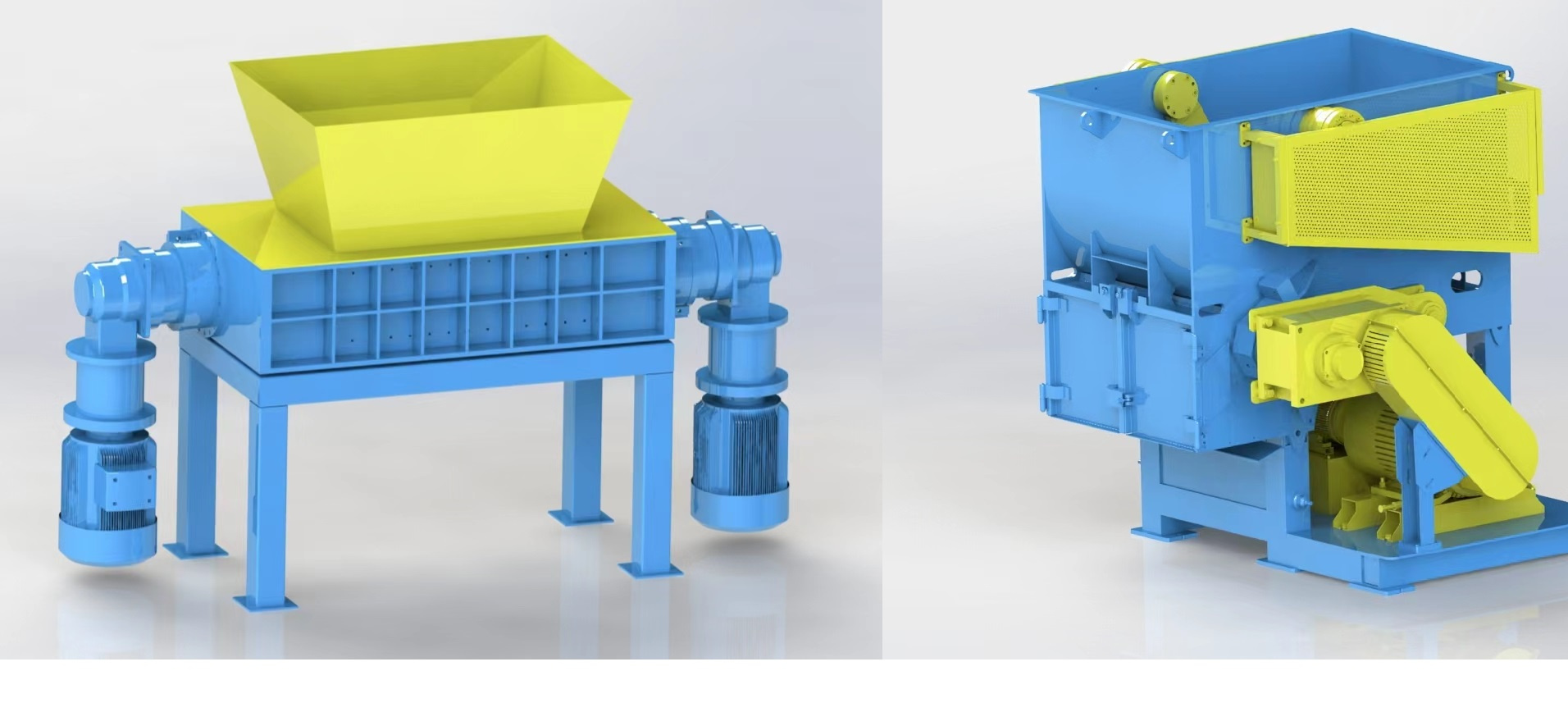

First, the composition structure is different

The double-shaft shredder is mainly composed of shredding

blade group, bearing box, box bracket, feeding system, power system, and

electrical control system. The principle of mutual shearing and tearing of two

relatively rotating knife roller tools is used to crush the material. The

material enters the inside of the shredding box, and after the comprehensive

action of tearing, extrusion, shearing and other comprehensive effects of the

shredding blade, the material is shredded into small pieces, and discharged

through the discharge hole under the equipment, and the subsequent material is

sent out through the conveyor belt for further crushing treatment.

The single-shaft shredder is mainly composed of spindle,

blade, fixed knife, bearing box, box bracket, feeding system, pushing system,

power system, electrical control system, etc. The material enters the inside of

the shredding box through the feeding system, the box body is loaded with a

shredding blade, the pushing box pushes the material to the vicinity of the

blade, and the material is torn into small pieces of material through the

comprehensive effect of tearing and extrusion by the shredding blade, and

discharged from the screen hole to achieve material shredding.

Second, the knife type is different

The moving shaft of the double-shaft shredder becomes

two, both inlaid with blades, and the two shafts rotate opposite each other,

and the material is operated similar to that of a single-shaft shredder. The

single-shaft shredder is equipped with only one moving shaft, on which the

blades are mounted and cut each other with the fixed knife on the box.

Third, the working principle is different

The double-shaft shredder adopts the drive of

"double motor + double planetary reducer", which uses the principle

of mutual shearing and tearing between two relatively rotating tools to crush

the material. The single-shaft shredder adopts a single-shaft "motor +

reducer" drive design, which provides large shear force and ensures high

crushing efficiency. It is often used for the fine crushing of solid waste, and

the material can be processed to a smaller particle size at one time.

Fourth, the crushed materials are different

The double-shaft shredder adopts reducer drive, which has

low speed and large torque, high crushing efficiency and stronger

applicability. It is suitable for shredding domestic waste, industrial waste,

electronic waste, biomass, kitchen waste, medical waste, wood and other materials

with large volume and high hardness.

The materials shredded by single-shaft shredders are more

limited than those of double-shaft shredders, and are often used in paper

mills, waste fabrics, leather scraps, PE, PP plastic pipes, plastic films,

woven bags, wires and cables, cans, aluminum chips and other aluminum products.

However, because the single-shaft shredder works together through the fixed

knife and the moving knife, the equipment torque is limited, and the size of

the feed bin is limited, so the single-shaft shredder is smaller than the double-shaft

shredder.

Welcome

to contact us for more detailed product information. We can recommend the

selection of appropriate models, integrated to meet the production needs of the

program. Allow customers to control the investment as far as possible, access

to high cost-effective equipment products or production lines.

CN

CN EN

EN

TEL:086-0533-3588750

TEL:086-0533-3588750 FAX:086-0533-3588750

FAX:086-0533-3588750 E-MAIL:info@utshredder.com

E-MAIL:info@utshredder.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,