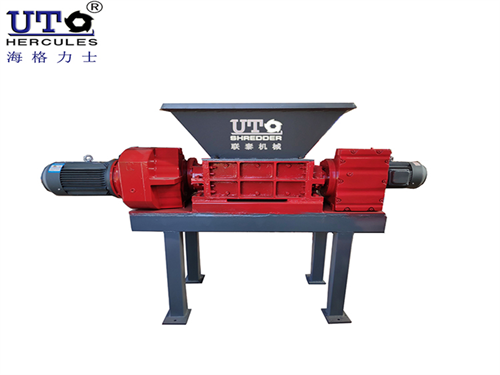

Understanding the characteristics of tearing, especially in the context of shredding or tearing machines, involves recognizing several key aspects:

1. Mechanism: Tearing typically involves the application of force to a material, causing it to break apart along weak points or predetermined lines. In shredding machines, this force is often applied through rotating blades or cutting elements that shear or tear the material apart.

2. Particle Size: The tearing process results in the creation of smaller pieces or particles from a larger material. The size of these particles can vary depending on factors such as the design of the tearing machine and the specific properties of the material being torn.

3. Uniformity: The tearing process may produce particles of varying sizes, leading to a heterogeneous mixture of shredded material. However, in some applications, it's desirable to achieve a more uniform particle size distribution to optimize downstream processes like sorting or recycling.

4. Material Properties: Different materials exhibit varying behaviors when torn. For example, brittle materials like certain plastics may fracture more readily, resulting in sharp-edged particles, while ductile materials like rubber may deform or stretch before tearing.

5. Energy Consumption: Tearing materials requires energy input, which can vary depending on factors such as the material's toughness, the design of the tearing machine, and the desired particle size distribution. Minimizing energy consumption while maximizing tearing efficiency is often a consideration in machine design.

6. Safety Considerations: Tearing machines, especially those with high-powered mechanisms like industrial shredders, pose safety risks to operators. Proper safety precautions, including guarding, emergency stops, and training, are essential to mitigate these risks.

7. Application Specificity: The characteristics of tearing can vary depending on the specific application and requirements. For example, the tearing of documents for disposal may prioritize particle size reduction and uniformity, while the tearing of scrap metal for recycling may focus on maximizing material recovery.

Understanding these characteristics allows for the effective operation and optimization of tearing processes, whether in industrial shredding applications, recycling facilities, or other contexts where material breakdown is required.

CN

CN EN

EN

TEL:086-0533-3588750

TEL:086-0533-3588750 FAX:086-0533-3588750

FAX:086-0533-3588750 E-MAIL:info@utshredder.com

E-MAIL:info@utshredder.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,